Solitary bees need shelter. Most native bees do not live in hives. They nest alone in hollow stems, wood cavities, and soil tunnels.

A bee hotel provides artificial nesting sites using materials already available around the home or farm. The entire structure can be built from reclaimed items. Nothing new required.

This project takes one afternoon to one day, depending on your skills. The result lasts for years with basic seasonal care, and understanding that inner tubes/blocks are semi‑disposable.

What Is a Bee Hotel?

A bee hotel is a wooden frame filled with tubes and cavities. Solitary bees lay eggs inside these tunnels. Each tube becomes a nursery for the next generation.

Mason bees and leafcutter bees are the primary occupants. These species are exceptional pollinators. A single mason bee pollinates at a rate 100 times greater than a honeybee.

The hotel design generally avoids attracting honeybees or wasps in significant numbers. The design and hole size favor solitary bees but some beneficial wasps may also use them.

What Materials Work Best?

The frame requires untreated wood. Chemical treatments harm bees. Reclaimed barn wood, old fence boards, and scrap lumber all work.

Minimum dimensions:

- Depth: 8inches or more

- Width: 10 inches or more

- Back: Closed and solid

- Front: Open for bee access

Nesting materials fill the interior. Multiple options exist.

Hollow stems and reeds:

- Bamboo canes cut to frame depth

- Dried plant stalks from gardens

- Hollow raspberry or elderberry stems

Drilled wood blocks:

- Hardwood scraps with holes drilled at varying diameters

- Hole sizes range from 1/16 inch to 5/8 inch

- Holes must not breach the back of the block

Collected natural materials:

- Dried sunflower stalks

- Teasel stems

- Any hollow, smooth-walled plant material

All materials must be dry. Moisture causes mold. Mold kills larvae.

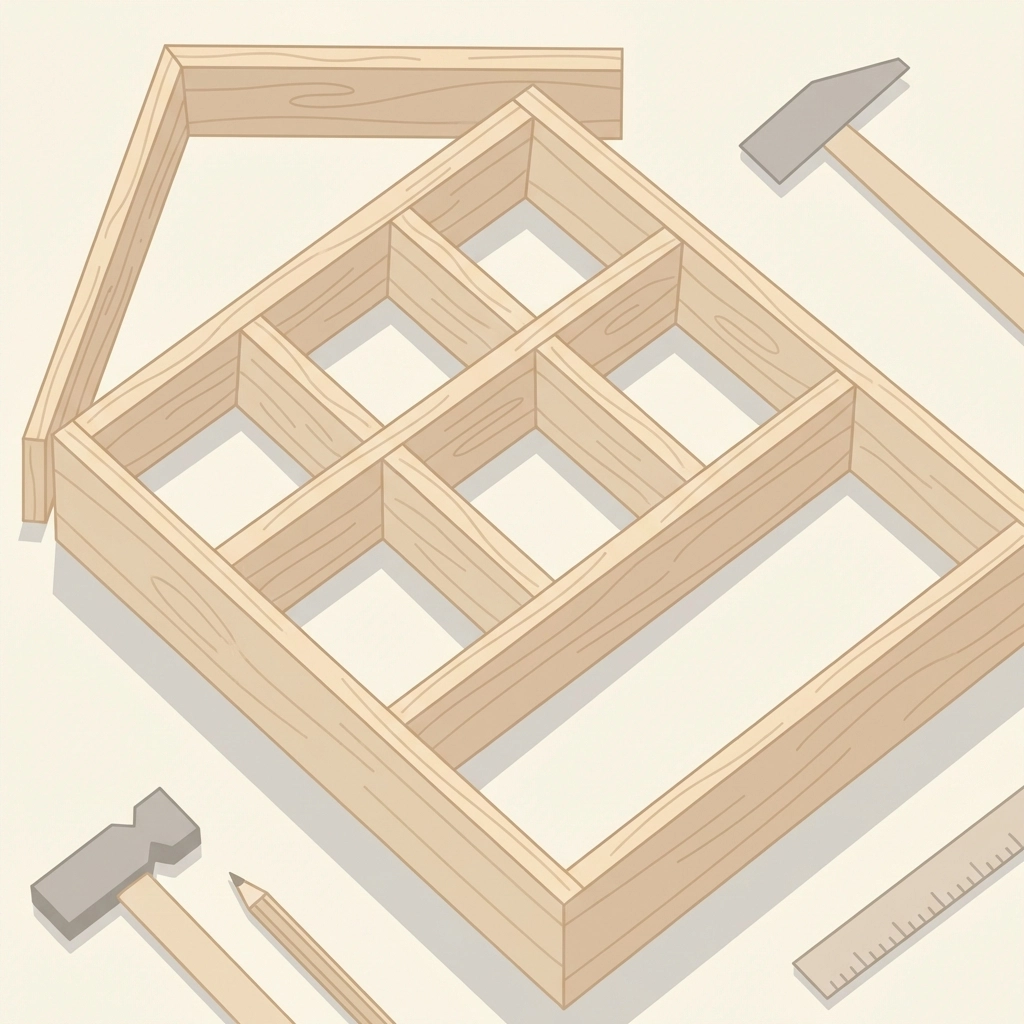

What Tools Are Needed?

Basic hand tools complete this project.

- Saw (hand saw or circular)

- Drill with multiple bit sizes

- Screws or nails

- Sandpaper (medium grit)

- Wood glue (optional)

- Pruning shears for cutting stems

No specialized equipment required. No power tools necessary beyond a drill.

How to Build the Frame

Step 1: Cut the back panel.

A solid piece of untreated wood forms the rear wall. Dimensions depend on desired hotel size. A 12-inch by 12-inch square works well for a starter hotel.

Step 2: Attach side walls.

Cut two side pieces the same height as the back panel. Depth should be 6 to 8 inches. Screw or nail these perpendicular to the back panel, creating a box shape.

Step 3: Add top and bottom.

Cut pieces to span the width of the box. Attach with screws. The structure now resembles an open-faced wooden crate.

Step 4: Create a sloped roof.

Rain destroys bee hotels. A simple angled roof deflects water. Cut a board slightly wider than the frame. Attach at an angle so water runs off the front.

The frame is complete. No paint or stain needed. Raw wood weathers naturally.

How to Prepare the Nesting Tubes

Bamboo and hollow stems:

Cut each piece to match the frame depth. Tubes should sit flush with the front opening. No overhang.

Remove any internal nodes from bamboo. A long drill bit or metal rod clears obstructions. Bees need unobstructed tunnels.

Sand the front edges smooth. Splintered openings deter nesting. Rough edges can damage delicate bee wings.

Drilled wood blocks:

Select hardwood scraps. Softwoods splinter and absorb moisture.

Drill holes at varying diameters:

- 5/64–3/8 inch for small species

- 1/4–3/8 inch for mason bees

- 1/8–1/4 inch for leafcutter bees

- 5/8 inch for larger native species

Drill to a depth of 4 to 6 inches. Do not drill through the back. Dead-end tunnels are essential.

Remove all sawdust. A pipe cleaner or compressed air clears debris. Sawdust blocks female bees from laying eggs.

How to Assemble the Hotel

Pack nesting materials tightly into the frame. No gaps between tubes. Loose packing allows parasites to enter.

Mix materials for variety. Different bee species prefer different diameters. A diverse hotel attracts diverse pollinators.

Drilled wood blocks can anchor the center. Surround them with hollow stems and bamboo. The combination creates visual interest and functional variety.

Fill every space. Empty areas attract unwanted insects. Tight packing ensures structural stability.

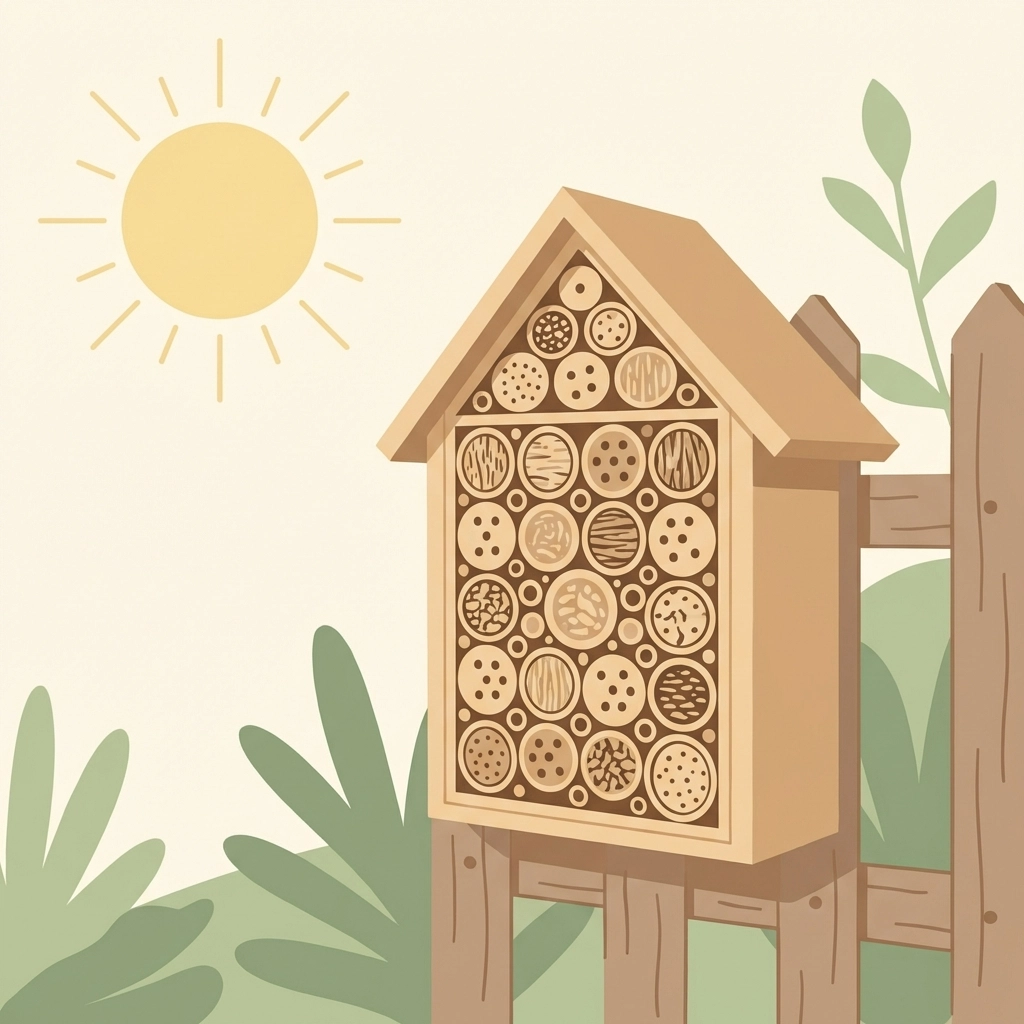

Where Should the Bee Hotel Go?

Location determines success.

Direction: Face the opening South to Southeast. Morning sun warms the hotel. Warm bees emerge earlier and work longer.

Height: Mount 3 to 5 feet off the ground. This height discourages ground predators. It also keeps the hotel dry during heavy rain.

Stability: Attach firmly to a post, fence, or building. Swinging or wobbling hotels deter nesting. Bees require stable environments for egg-laying.

Shelter: Partial shade in afternoon prevents overheating. Full sun all day bakes the larvae. A spot under eaves or near trees works well.

Timing: Install in early spring. The period around last frost marks peak mason bee emergence. Hotels placed later miss the primary nesting season.

How to Maintain the Hotel Year After Year

Bee hotels require seasonal attention. Neglected hotels become parasite breeding grounds.

Fall tasks:

Remove used nesting tubes after bees have sealed their chambers. Sealed tubes appear capped with mud or leaf material.

Store tubes in a cool, dry location. A garden shed or unheated garage works. Temperatures should remain cold but above freezing.

Winter tasks:

Clean the empty frame with boiling water. A stiff brush removes debris, mold spores, and parasites. Allow complete drying before spring.

Inspect stored tubes for damage. Discard any with visible mold or holes from parasitic wasps.

Spring tasks:

Return stored tubes to the frame. Add fresh nesting materials alongside the old ones.

Emerging bees chew through their sealed chambers. They mate and seek new tubes for egg-laying. Fresh materials accommodate the new generation.

This cycle repeats annually. The frame lasts indefinitely with proper care. Nesting materials refresh each year at zero cost.

What Mistakes Should Be Avoided?

Using treated wood.

Pressure-treated lumber contains chemicals toxic to bees. Painted or stained wood off-gasses harmful compounds. Raw, untreated wood only.

Drilling through wood blocks.

Holes must be dead ends. Through-holes expose larvae to predators and temperature fluctuations.

Ignoring moisture.

Wet hotels grow mold. Mold kills developing bees. The sloped roof, proper placement, and dry materials prevent this.

Skipping maintenance.

Abandoned hotels accumulate parasites. Pollen mites, parasitic wasps, and fungal infections spread through neglected structures. Annual cleaning eliminates these threats.

Using plastic straws or synthetic materials.

Plastic does not breathe. Condensation builds inside. Natural materials regulate humidity.

What Results Can Be Expected?

Occupancy varies by location and season. A well-placed hotel in a garden-rich area fills within weeks.

Signs of activity:

- Mud caps on tube openings (mason bees)

- Leaf fragments sealing tubes (leafcutter bees)

- Bees hovering near the hotel entrance

Pollination increases noticeably. Vegetable gardens, fruit trees, and flower beds benefit directly.

The hotel becomes a permanent fixture. Each spring brings returning generations. Each fall offers the satisfaction of a full, productive structure.

One afternoon of work. Years of ecological benefit. Zero waste.